Aviation refueler truck

Aviation refueler truck (also called aircraft refueler truck, helicopter refueler truck, fuel dispenser truck, oil bowser truck, off road refueling truck, 4X4 aviation refueling truck) is used to transport Jet A, aviation fuel, fuel, oil, diesel, gasoline, kerosene and so on.

Description

Aviation refueler truck (also called aircraft refueler truck, helicopter refueler truck, fuel dispenser truck, oil bowser truck, off road refueling truck, 4X4 aviation refueling truck) is used to transport Jet A, aviation fuel, fuel, oil, diesel, gasoline, kerosene and so on.

-

Aviation refueler truck body: The tanker material is made of aluminum-magnesium alloy 5083 with advantage of light weight, large volume, corrosion resistance and no pollution and guarantees the quality of oil.

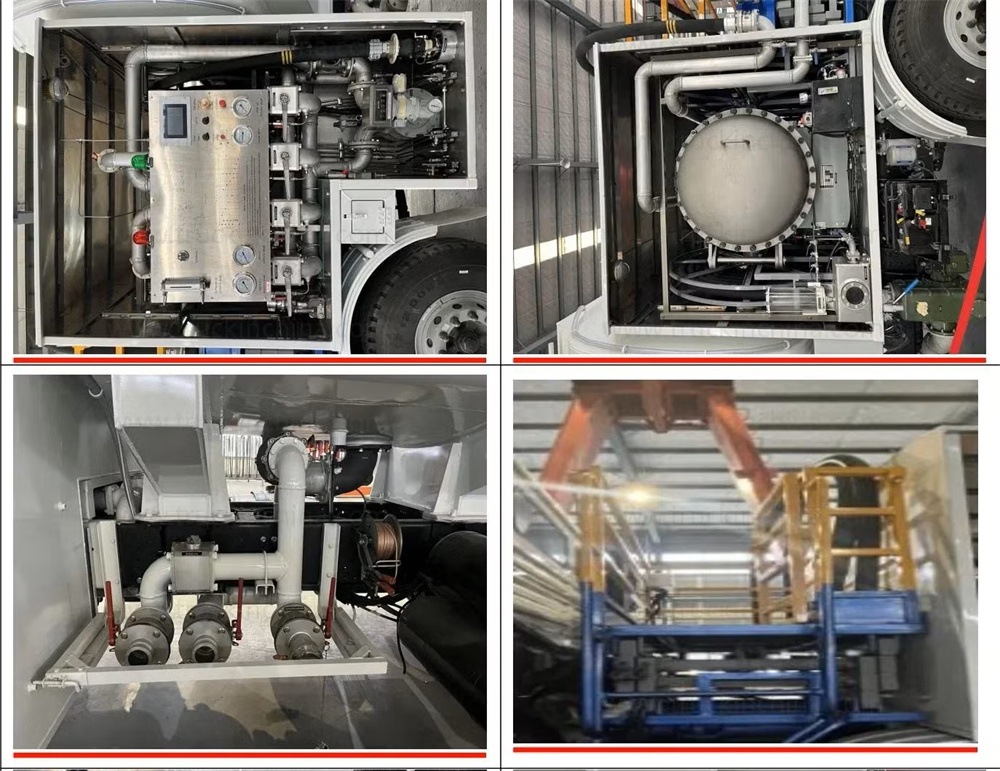

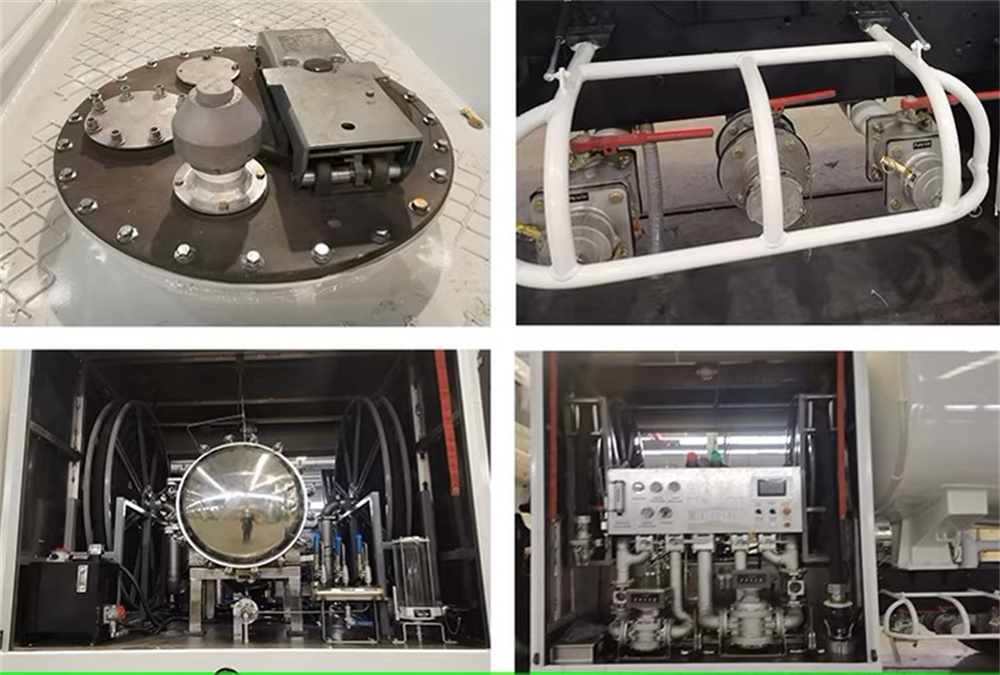

2. Aviation refueler truck: aluminum alloy centrifugal pump, reel filling flow 80 or 300L / min, pipeline pumping flow 700L / min, working pressure is 0.25MPa.

3. Aviation refueler truck flowmeter: 0.2 accuracy, diameter 50 waist wheel flowmeter.

-

Filter separator: rated flow 400L / min, rated working pressure 1.0MPa, the maximum allowable pressure difference of 0.15MPa, in line with the requirements of API 1581 3rd edition.

5. Automatic reset reel, refueling hose diameter 25 or 38MM, length 15 meters.

6. Level gauge: The stainless steel float in the tank and the 10-inch aluminum alloy dial on the left side of the tank can clearly observe the current liquid volume in the tank.

7. Operating system: centralized control of independent control room, instrument indication includes pump inlet vacuum gauge, pumping pressure gauge, oil pump tachometer, filter differential pressure gauge, etc. Switch valve operation includes power main switch, lighting switch, emergency stop switch, oil pump adjustment knob, fueling valve, circulating filter valve, sampling valve, subsea valve control combination switch, etc.

Feature

–High quality carbon steel material;

–Independent compartment for different types of fuel types;

–Several baffles inside tank to improve safety performance;

–High pressure gas leakage test to ensure tank safety;

–The tank shape adopts advanced welding technology and arc butt welding technology of the head as well as the integral one forming technology, fast installation, convenient maintenance, beautiful appearance.

–Choose high quality domestic or imported safety accessories, carburetor and pump for users to choose, complete supporting.

–Strictly adopt scientific advanced construction technology to ensure the lowest shrinkage rate and the highest dimensional stability in the low temperature state.